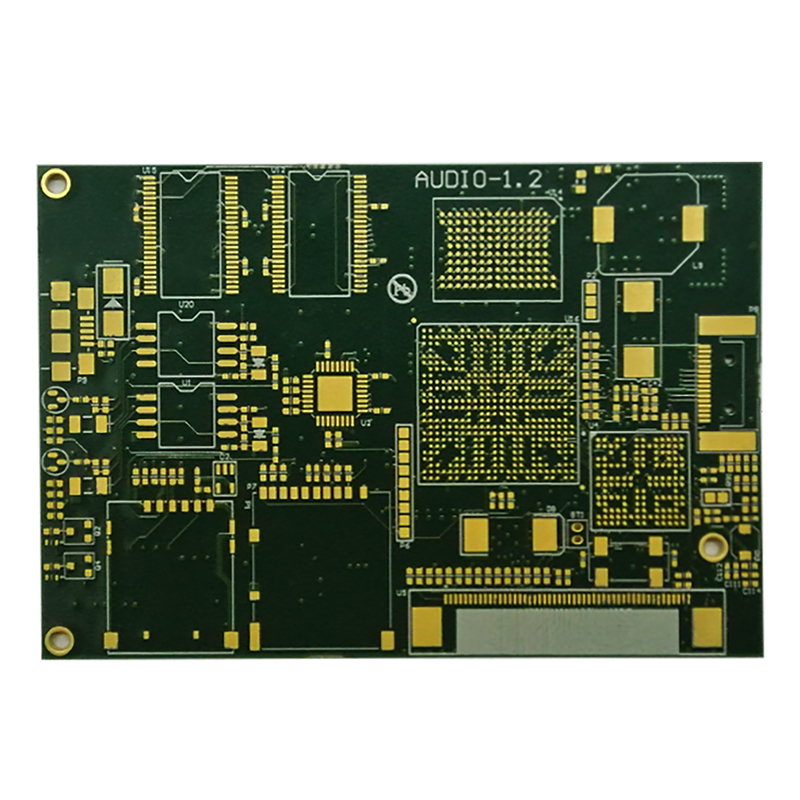

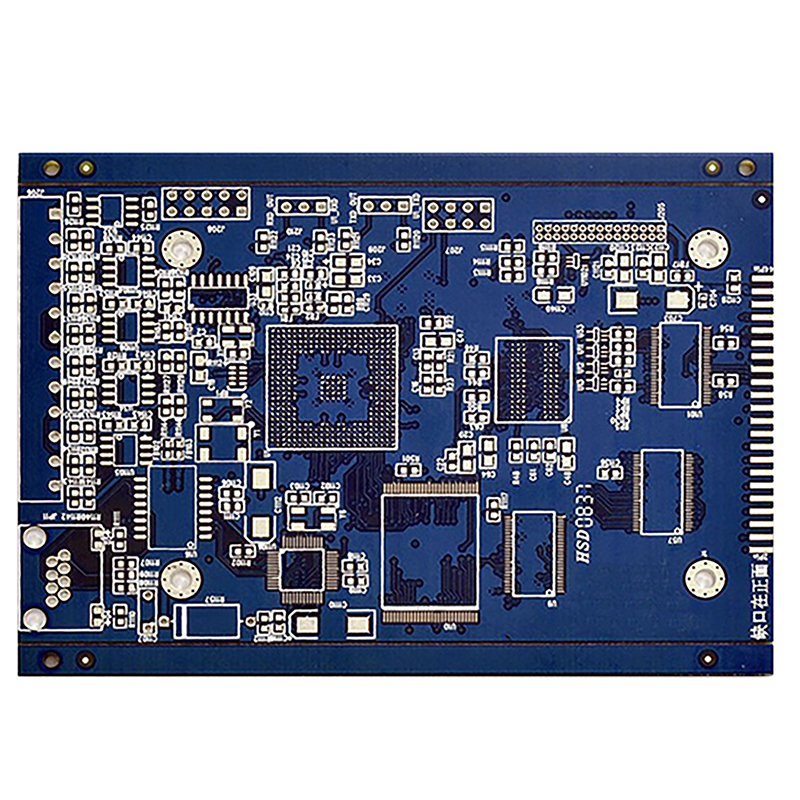

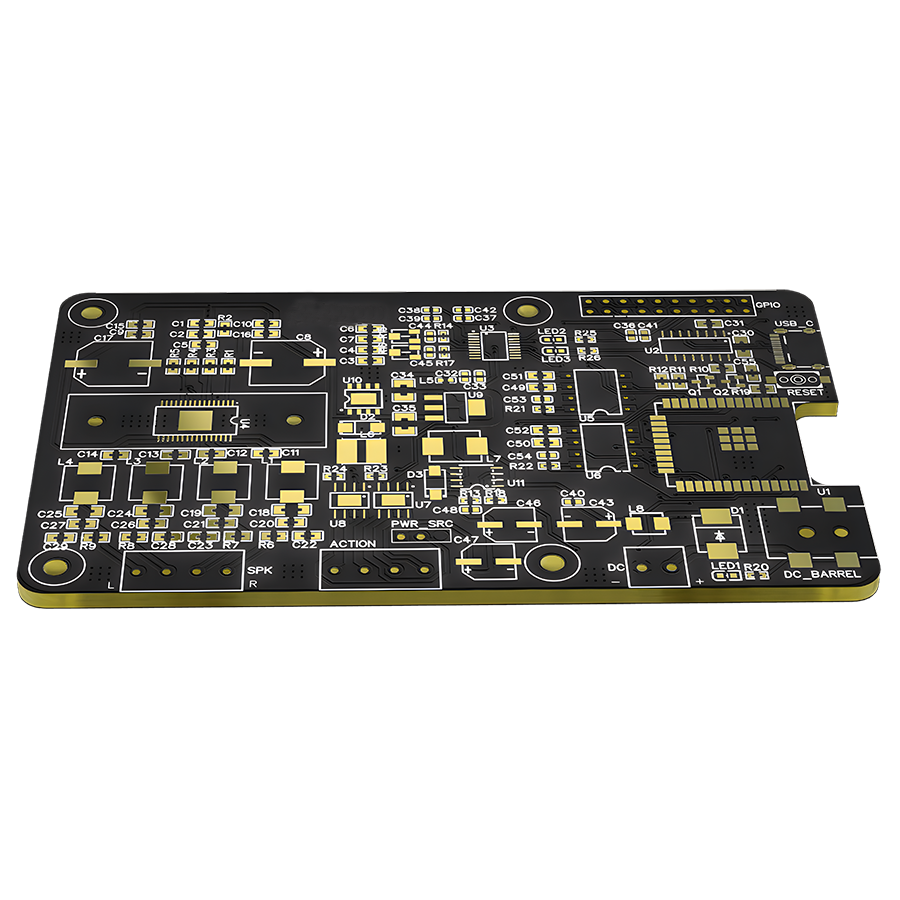

FR-4|Advanced PCB

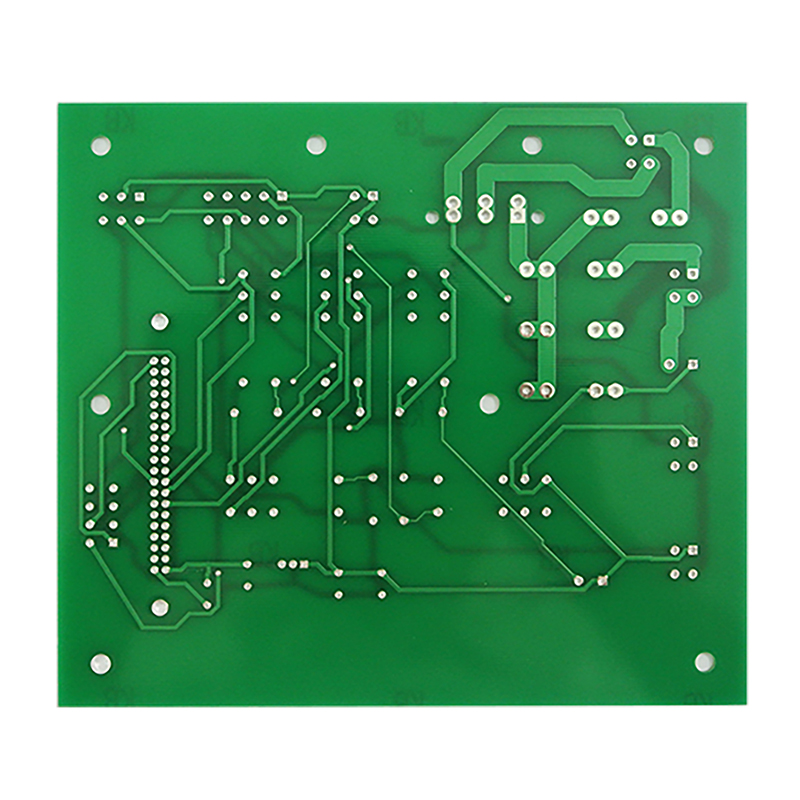

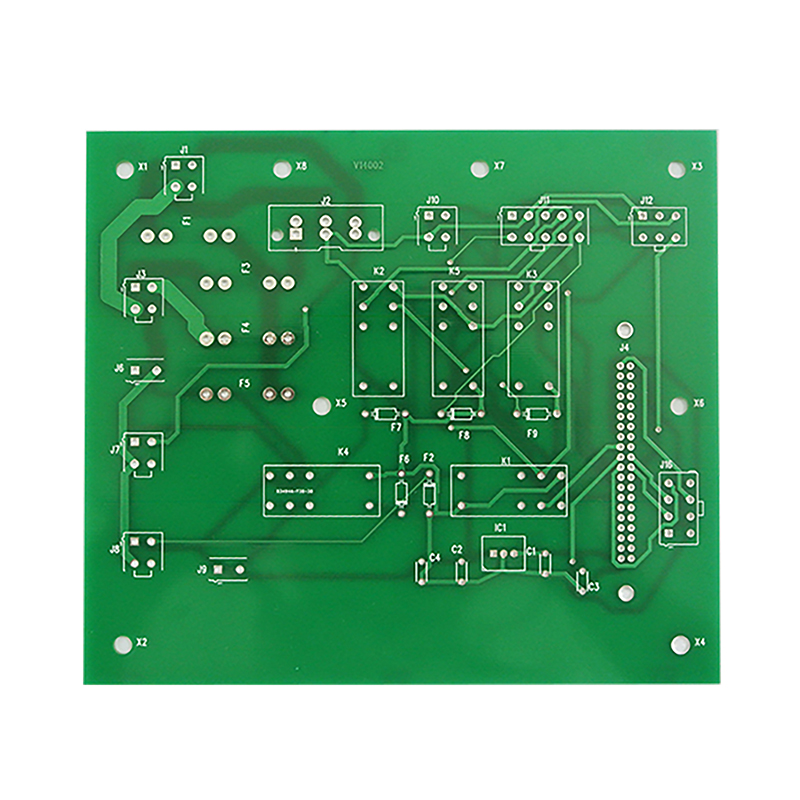

PCB sampling and mass production services from 1 to 42 layers. We use real A-grade plates, adhere to the factory's self-operated production model, and ensure the reliability and stability of quality. Brand new high-rise dedicated production line, the circuit soldering prevention adopts advanced production equipment in the industry such as LDI, VCP pulse plating, etc., uses famous brand plates, precise impedance detection instruments, and provides high-definition characters, high-quality inspection standards, high-end packaging and transportation services.

| Multi-Layers(Partial Technology Capability) | ||

| Layer count | 1~42L | |

| Core thickness(Exclude copper) | 50um | |

| Min mechanical hole size | 100um | |

| Inner outter layer registration Mini pad Dia. | DHS+6mil | |

| Min. S/M dam | 50um | |

| Min. S/M opening size | 4mil | |

| Via Covering | Epoxy Filled & Untented, Epoxy Filled & Capped,Copper paste Filled & Capped | |

| Solder mask color |  |

|

| Solder mask ink thickness | ≧10um | |

| Depth-Controlled routing tolerance | ±0.05mm | |

| Minimum Legend Width | 6mil(0.15mm) | |

| Surface Finish |

HASL/ImmersionTin/ImmersionSilver /ImmersionGold/ENEPIG/OSP |

|

For more information, please click 【here】.

PTFE Teflon high-frequency board

| Partial PCB Process Parameters | |

| Base Material | PTFE Teflon |

| Layers | 2Layers |

| Maximum Dimensions | 590mm*438mm |

| PCB Thickness | 0.76mm~1.65mm |

| PCB Color |  |

| Silkscreen |  |

| Material Type |

ZYF255DA(Dk=2.55,Df=0.0018), ZYF265D(Dk=2.65,Df=0.0019), ZYF300CA-C(Dk=2.94,Df=0.0016), ZYF300CA-P(Dk=3.0,Df=0.0018), [Data Sheet] |

| Surface Finish | ENIG |

| Gold Thickness | 1μ'', 2μ'' |

| Outer Copper Weight | 1oz |

| Via Covering | Tented, Untented, Plugged, Epoxy Filled & Capped, Copper Paste Filled & Capped |

| Test | AOI, Flying Probe Test |

Rogers high-frequency board

| Partial PCB Process Parameters | |

| Base Material | Rogers |

| Maximum Dimensions | 590mm*438mm |

| Layers | 1Layer, 2Layers |

| PCB Thickness | 0.5mm~1.6mm |

| PCB Color |  |

| Silkscreen |  |

| Material Type | RO4350B(Dk=3.48,Df=0.0037) [Data Sheet] |

| Surface Finish | ENIG |

| Gold Thickness | 1μ'', 2μ'' |

| Outer Copper Weight | 1oz |

| Via Covering | Tented, Untented, Plugged, Epoxy Filled & Capped, Copper Paste Filled & Capped |

| Test | AOI, Flying Probe Test |

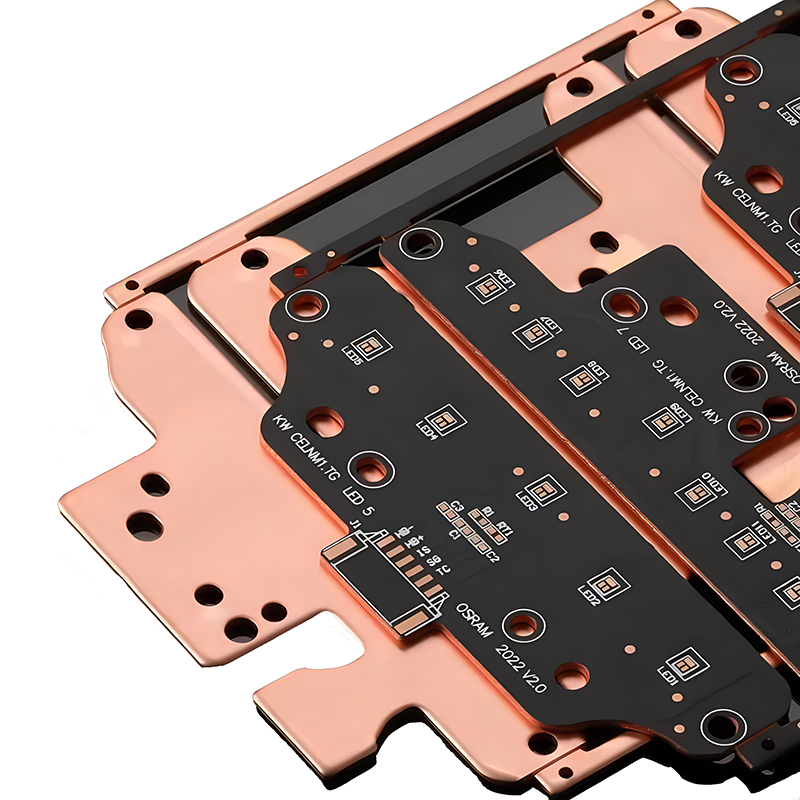

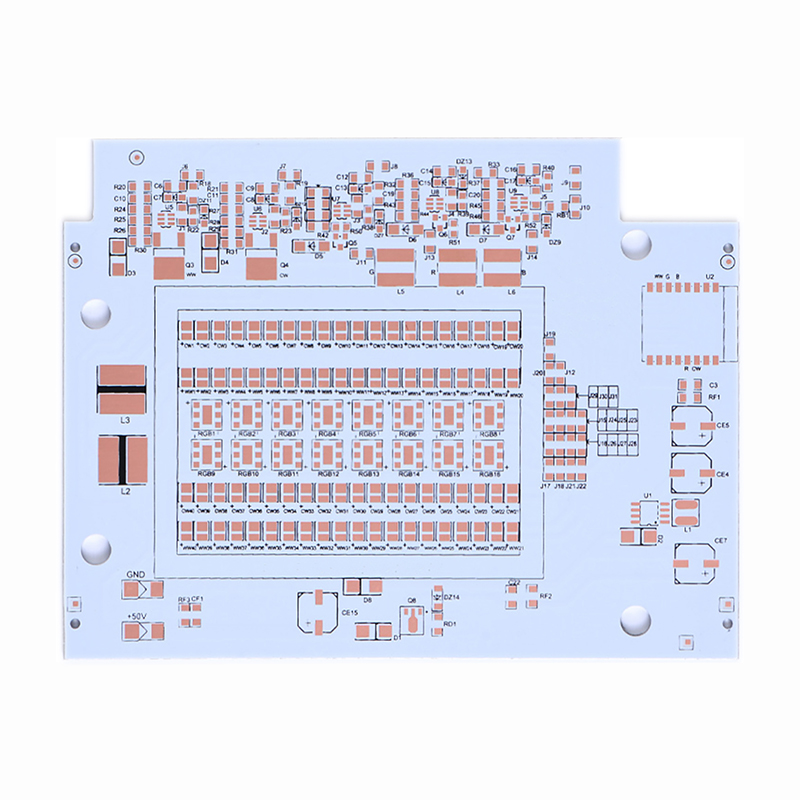

Copper Core PCB

We are a professional PCB manufacturer with guaranteed quality and fast delivery time, cooperating with both Chinese and global customers for over 15 years.

Board Type: Copper Core

Lead Time: Sample delivery in 12 hours (fastest)

Features: Sampling/Small-batch, Large-batch Multi-dimensional Production Mode

| Partial PCB Process Parameters | |

| PCB Thickness: | 1.0mm~2.0mm |

| Copper Structure: | Direct Heatsink |

| Thermal Conductivity: | 380W |

| Minimum Drill Size: | 1.0mm |

| Minimum Size: | 5*5mm |

| Maximum Size: | 480*286mm |

| Minimum Line Width/Spacing: | 0.1mm/0.1mm |

| PCB Color: |  |

| Silkscreen: |  |

| Surface Finish: | OSP, HASL(with lead), LeadFree HASL, ENIG |

Copper substrate is a high-performance base material known for its excellent thermal conductivity and electrical properties. This substrate is suitable for applications requiring high thermal stability and heat conduction efficiency, such as electronic product manufacturing, LED lighting, power supply modules, communication equipment, solar cells, and automotive electronics.

To learn more about our company's capabilities in copper substrate, please click [here].

Aluminum PCB

Aluminum substrate is a kind of metal-based copper-clad plate with good heat dissipation function. Generally, single-sided aluminum substrate consists of three layers: circuit layer (copper foil), insulation layer and metal substrate. It is often used in LED lighting and other products with large heat generation, and widely used in the fields of hybrid integrated circuits, lighting LEDs, automobiles, office automation, high-power electrical equipment, etc.

| Partial PCB Process Parameters | |

| PCB Thickness: | 0.8mm~1.6mm |

| Minimum drilling diameter: | 0.65mm |

| Minimum size: | 5*5mm |

| Maximum size: | 600*500mm |

| Minimum line width/line spacing: | 0.1mm/0.1mm |

| Breakdown Voltage: | 3000V |

| Thermal Conductivity: | 1W |

| Outer Copper Weight: | 1oz |

| PCB color: |  |

| Silkscreen: |  |

| Surface Finish: | HASL(with lead), LeadFree HASL, ENIG |

For more information about our capabilities in Aluminum PCB, please click [here] or contact us, and we will reply to you within 24 hours.

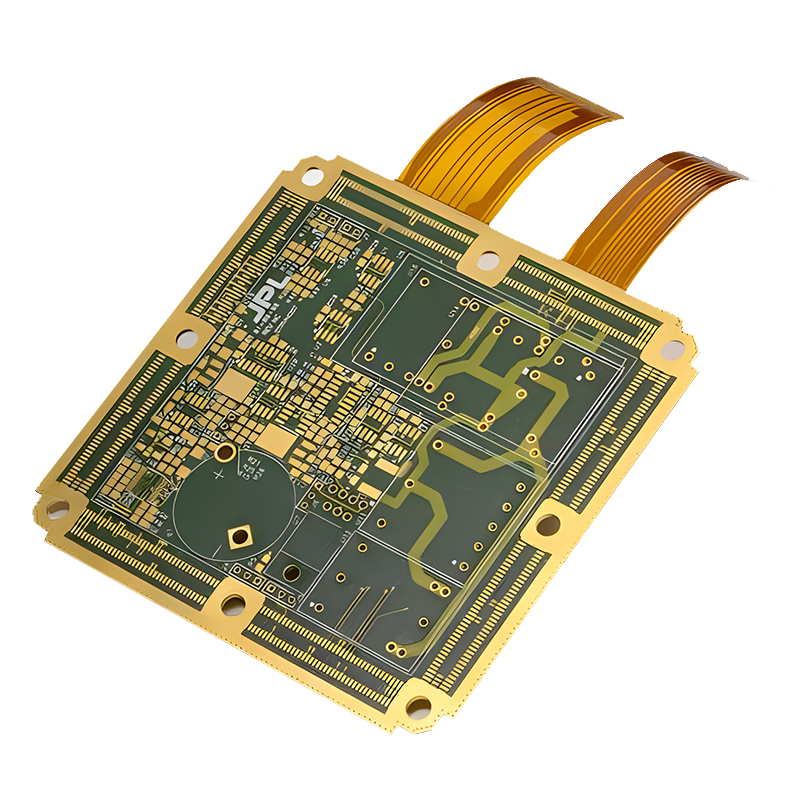

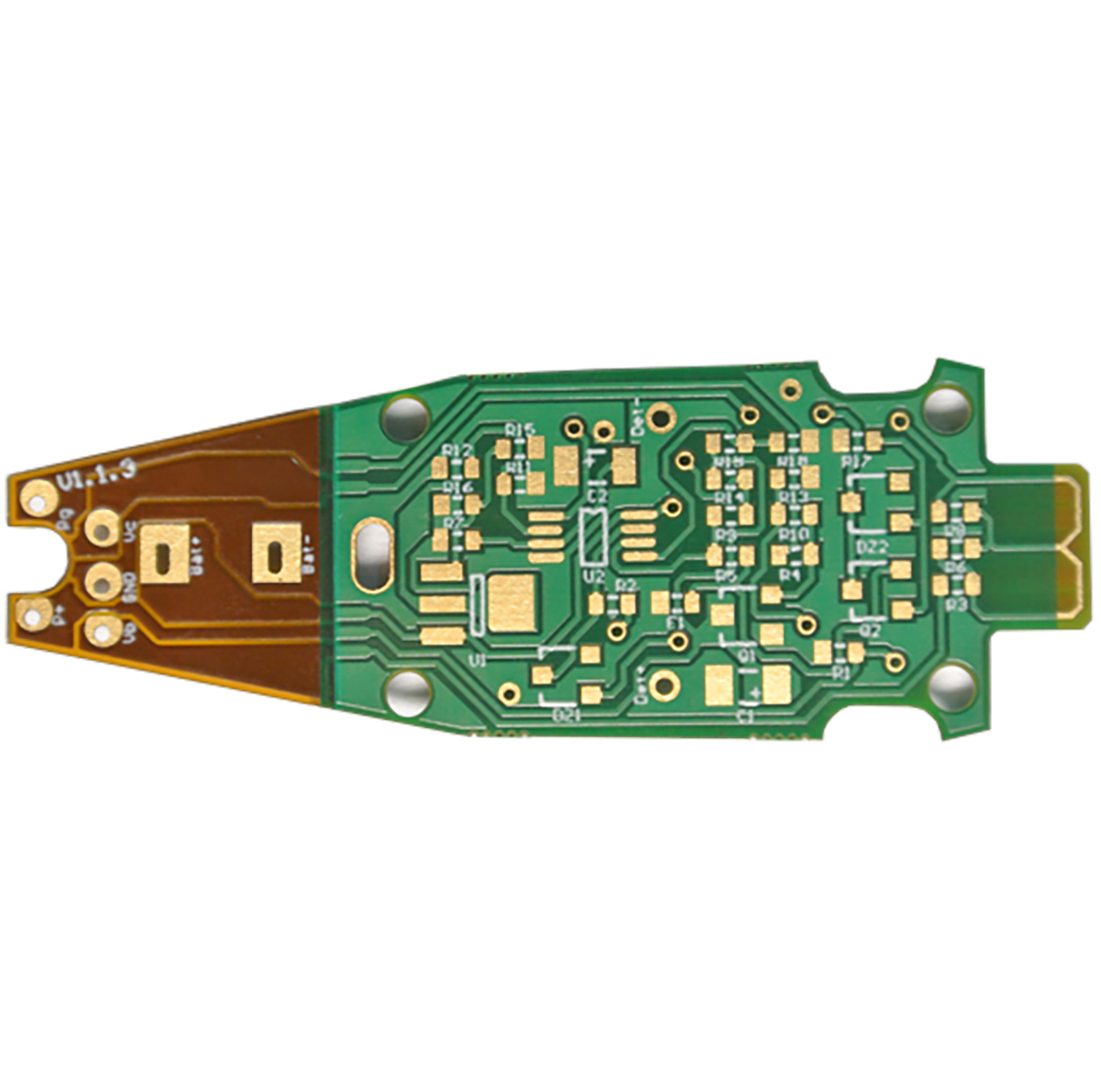

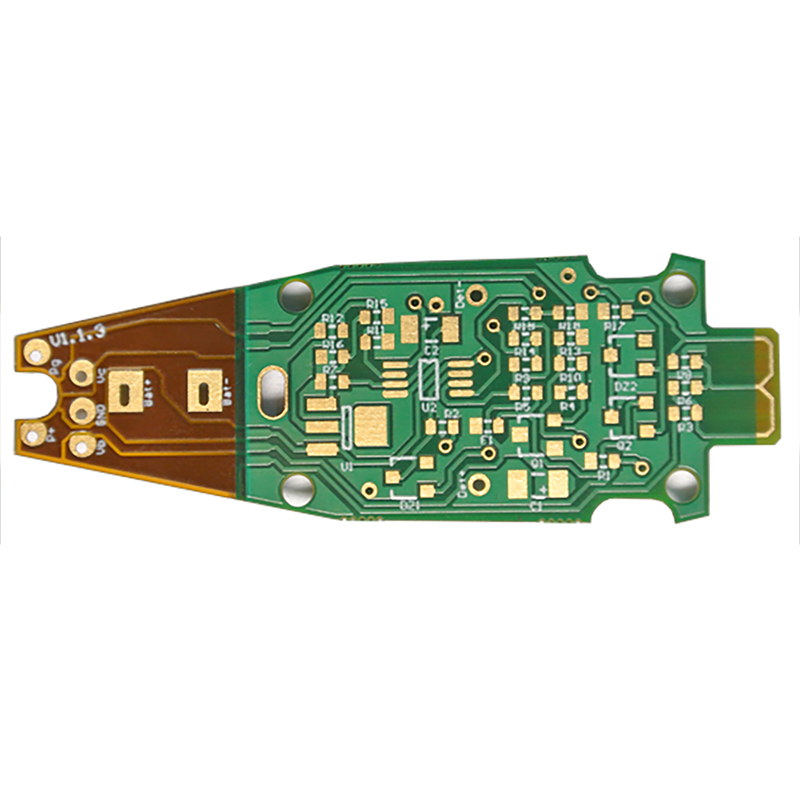

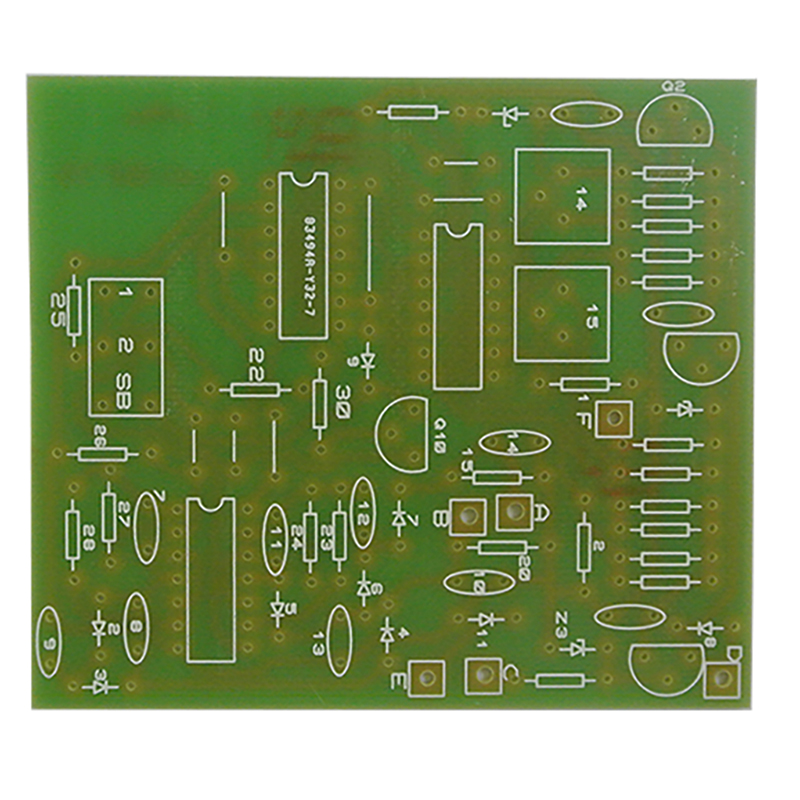

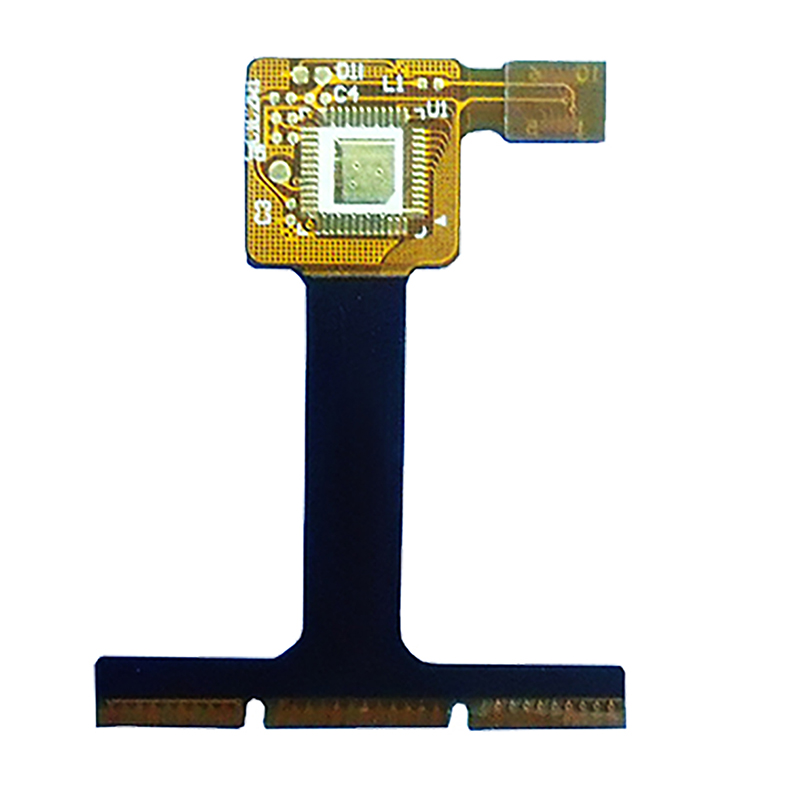

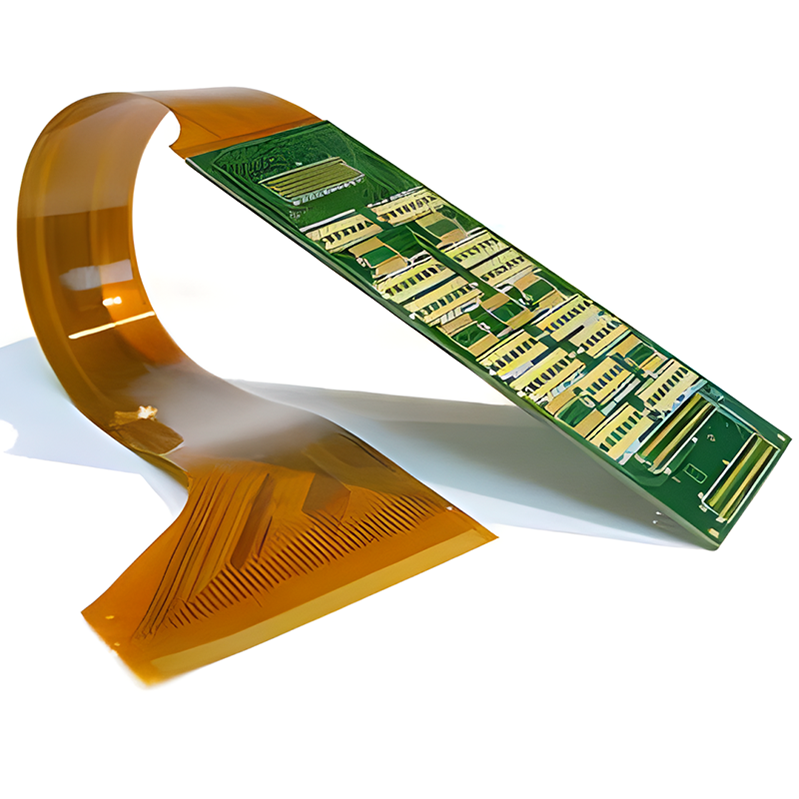

Flexible Printed Circuit (FPC) Boards

We are a professional flexible PCB&rigid-flex PCB manufacturer with guaranteed quality and fast lead time, cooperating with worldwide customers for over 15 years in China.

| Partial PCB Process Parameters | |

| Base Material: | FPC flexible board |

| Number of layers: | 1 layer, 2 layers, 4 layers, 6 layers, 8 layers |

| PCB Thickness: | 0.11mm~0.2mm |

| Outer Copper Weight: | 1/3 oz |

| Copper Type: | Electro-deposited |

| Coverlay color: |  |

| Coverlay Thickness: | PI: 12.5μm, AD: 15μm |

| Silkscreen: |  |

| Stiffener: | Polyimide, FR4, Stainless Steel, 3M Tape |

| EMI Shielding Film: | Single side(Black,18um), Both sides(Black,18um) |

| Surface Finish: | ENIG |

| Gold Thickness: | 1μ'', 2μ'' |

| Cutting Method: | Laser Cutting |

For more information about our capabilities in FPC manufacturing process, please click [here] or contact us, and we will reply to you within 24 hours.

PCB

PCB FPC

FPC Rigid-Flex

Rigid-Flex FR-4

FR-4 HDI PCB

HDI PCB Aluminum

Aluminum Copper Core

Copper Core PCB Assembly

PCB Assembly LED light PCBA

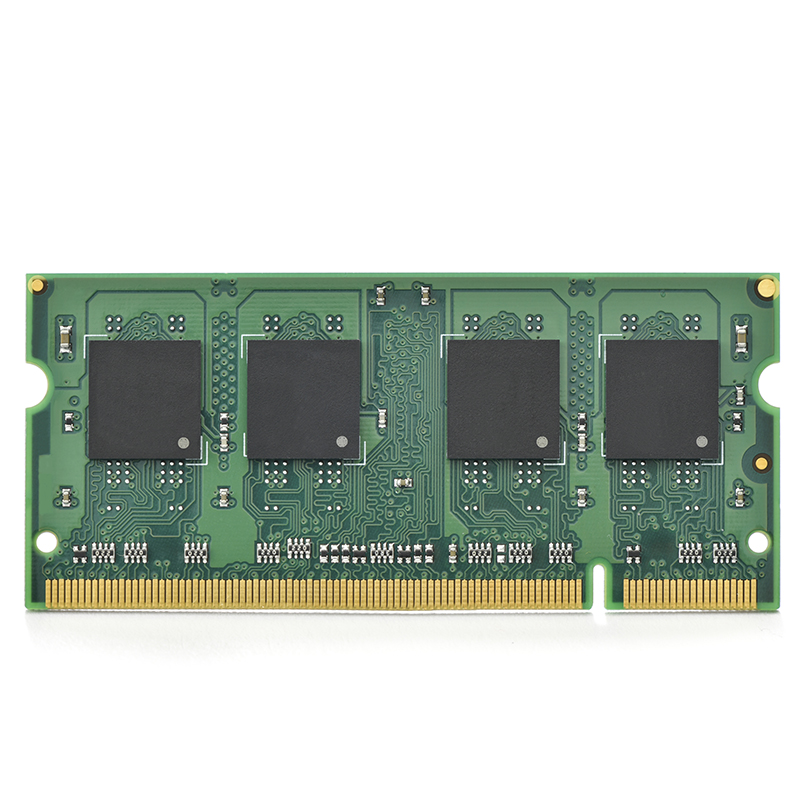

LED light PCBA Memory PCBA

Memory PCBA Power Supply PCBA

Power Supply PCBA New Energey PCBA

New Energey PCBA Communication PCBA

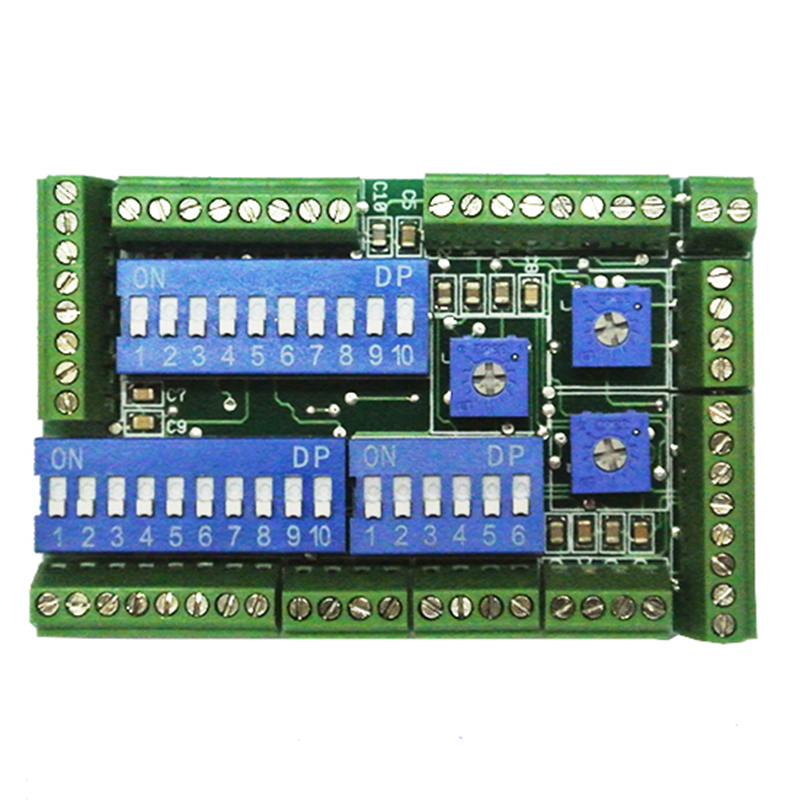

Communication PCBA Industrial Control PCBA

Industrial Control PCBA Medical Equipment PCBA

Medical Equipment PCBA Product Rebuild

Product Rebuild PCB Copy

PCB Copy IC Cracking

IC Cracking PCBA Testing Service

PCBA Testing Service Certification Application

Certification Application RoHS Certification Application

RoHS Certification Application REACH Certification Application

REACH Certification Application CE Certification Application

CE Certification Application FCC Certification Application

FCC Certification Application CQC Certification Application

CQC Certification Application UL Certification Application

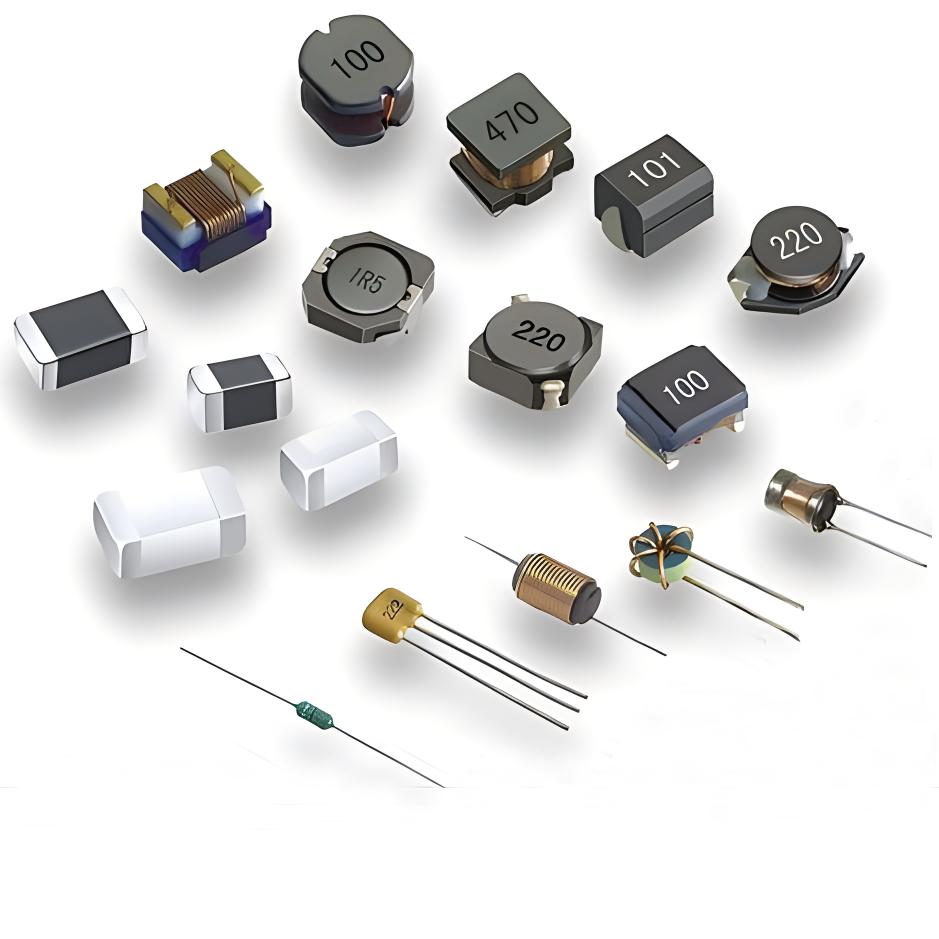

UL Certification Application Transformers, Inductors

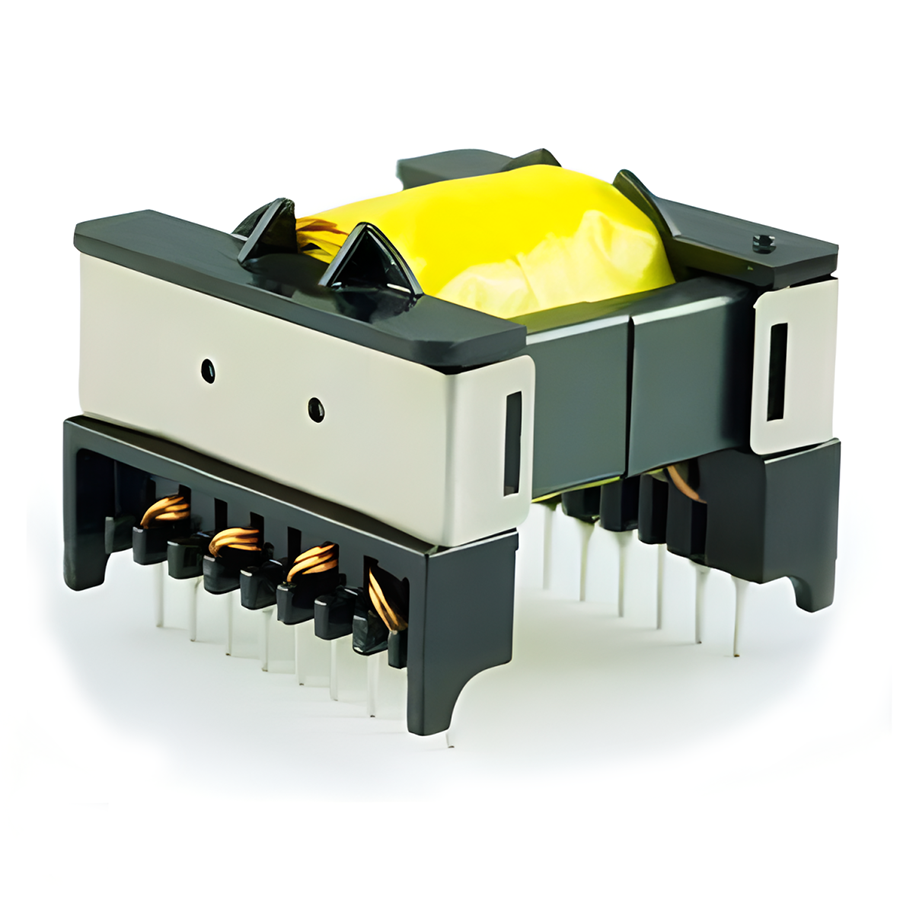

Transformers, Inductors High Frequency Transformers

High Frequency Transformers Low Frequency Transformers

Low Frequency Transformers High Power Transformers

High Power Transformers Conversion Transformers

Conversion Transformers Sealed Transformers

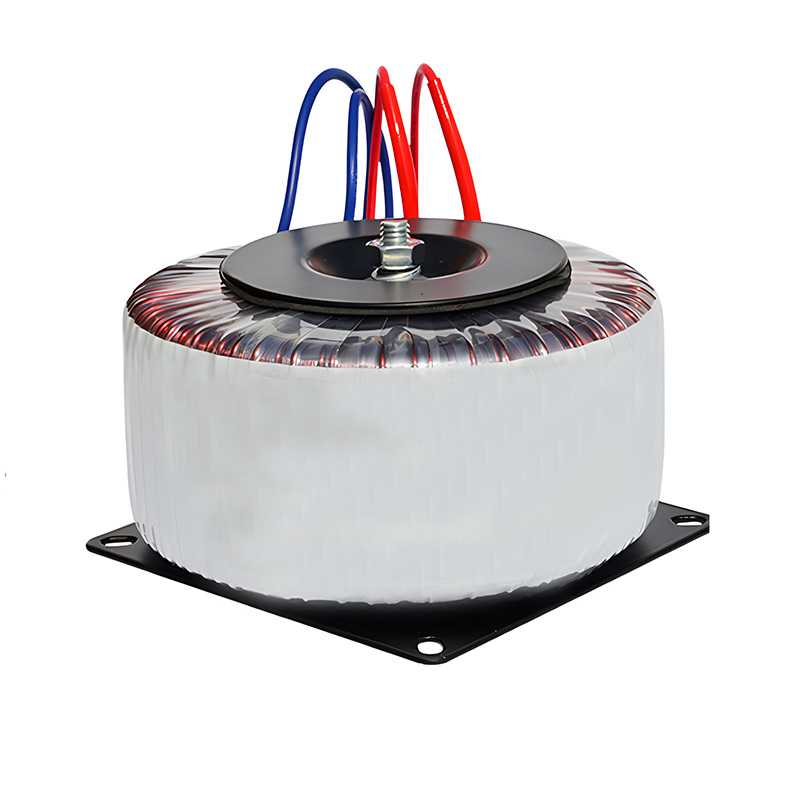

Sealed Transformers Ring Transformers

Ring Transformers Inductors

Inductors Wires,Cables Customized

Wires,Cables Customized Network Cables

Network Cables Power Cords

Power Cords Antenna Cables

Antenna Cables Coaxial Cables

Coaxial Cables Capacitors

Capacitors Connectors

Connectors Diodes

Diodes